Empowering Machine Vision Systems with Essential Components

At Saisadhana Solutions, we integrate advanced technologies to create machine vision systems that redefine industrial automation. Below, we explore the critical components that make these systems highly effective and reliable.

Components of Industrial Vision Solutions

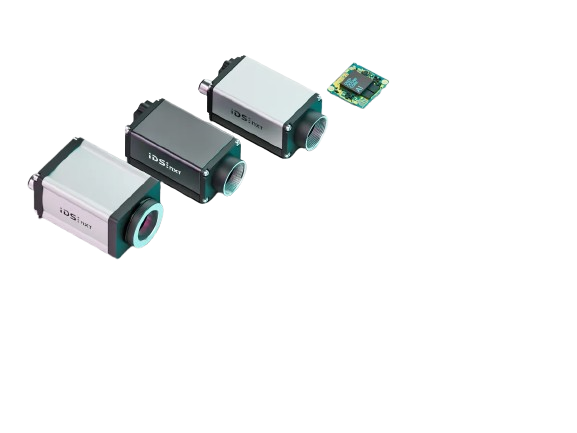

Vision camera sensor:

Captures high-quality images and videos with area-scan, line-scan, and 3D configurations for precise analysis and applications like defect detection and alignment.

Lens:

Focuses images onto the camera sensor for accurate data capture, essential for high-precision inspection and measurement tasks.

Software:

Processes captured images to deliver actionable insights through object recognition, defect detection, and pattern matching.

Lighting:

Provides consistent illumination to enhance image quality using LED, backlighting, or structured light for various inspection environments.

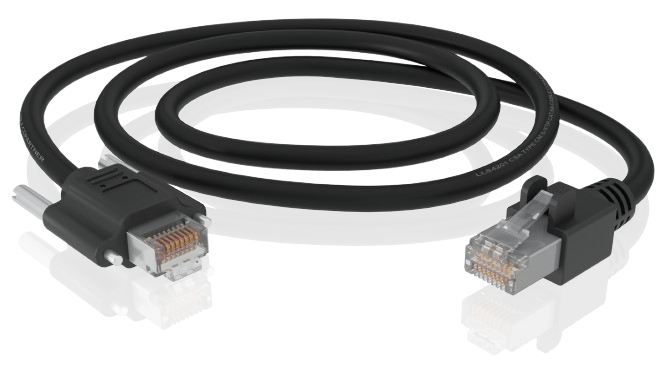

Communication cable:

Enables seamless data transfer between components and automation systems, ensuring integration with PLCs and robots.

Our Product Galery

Applications Across Industries

- Inspection: Detect defects in materials and ensure dimensional accuracy.

- Guidance: Position components accurately for assembly and production.

- Identification: Track products with barcode scanning and text recognition.

- Sorting: Classify items by size, shape, or color.

- Measurement: Achieve precise tolerances in critical manufacturing processes.

Why Choose Us:

Enhanced Precision: Capture and analyze visual data with unmatched accuracy.

Increased Efficiency: Automate repetitive tasks, reducing manual intervention.

Customizable Solutions: Adaptable components to meet specific industry requirements.

Scalability: Easily expandable to incorporate additional cameras, sensors, or new technologies.